Washington Pad

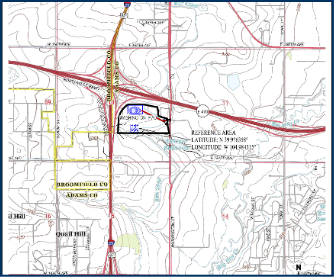

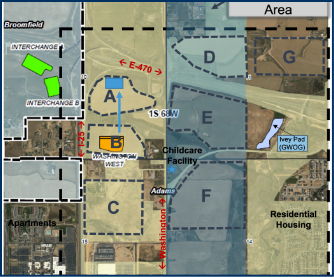

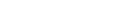

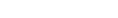

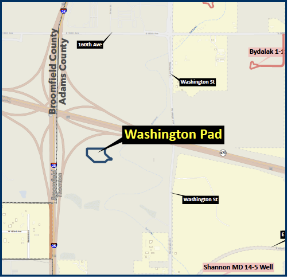

Overview & Location

Location History

Washington Pad Community Meeting

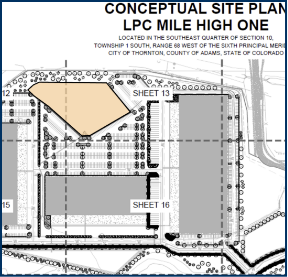

Current & Future Plans

Anticipated Timeline

Pad Construction Spring/Summer 2024

Construction of the pad will begin in the spring/summer 2024. This process will include construction of sound walls to minimize disturbance to the surrounding area. The process of constructing the pad and the sound walls is expected to be completed by summer 2024.

Drilling Operations Summer 2024

Next we will begin the work to drill the wells. This process will take place in summer 2024. During this process, we will construct multiple layers of steel and cement casing around each well to ensure wellbore integrity. The drilling rig will be visible and you should expect to see our crews in the area, as well as downcast lighting and additional truck traffic.

Completions Operations Summer/ Fall 2024

Once drilling is complete, the rig will leave the site. We will spend the next thirty days completing each well and preparing to bring them online. This stage should be complete by summer/fall of 2024.

Initial Production Year End 2024

We expect to reach the production preparation stage in YE 2024. During this phase, all excess operational equipment will be removed from the site. Only the wellheads and associated facilities will remain. To ensure safety and environmental compliance, the wells will be monitored 24/7 through automated remote equipment.

Interim Pad Reclamation Year End 2024

Once the wells are producing, there will be little to no associated traffic on a day-to-day basis. the pad area will be reduced and the surrounding area will be reclaimed with native vegetation. The wells will continue to produce for up to 30 years. We expect to reach the production stage in YE 2024.

Note: The times provided are estimates and are subject to local authorization. We will keep you informed of any significant changes to our plans.

Best-in-Class Operations and Mitigation

Civitas leads the industry in innovative technological advancements, environmental stewardship and dedication to the communities where we live and operate. Some of our Best Management Practices (BMPs) for the Washington pad will include:

Erection of sound walls around the location prior to the commencement of drilling, to remain until the completions phase is completed.

Use of a downcast lighting plan to minimize disturbance.

Use of a closed-loop fluid management system to reduce emissions and odor.

Installation of a hard-surface apron and technology to suppress dust.

Use of a temporary lay-flat water pipeline to reduce truck traffic during pre-production.