Bennett D (Watkins)

Overview & Location

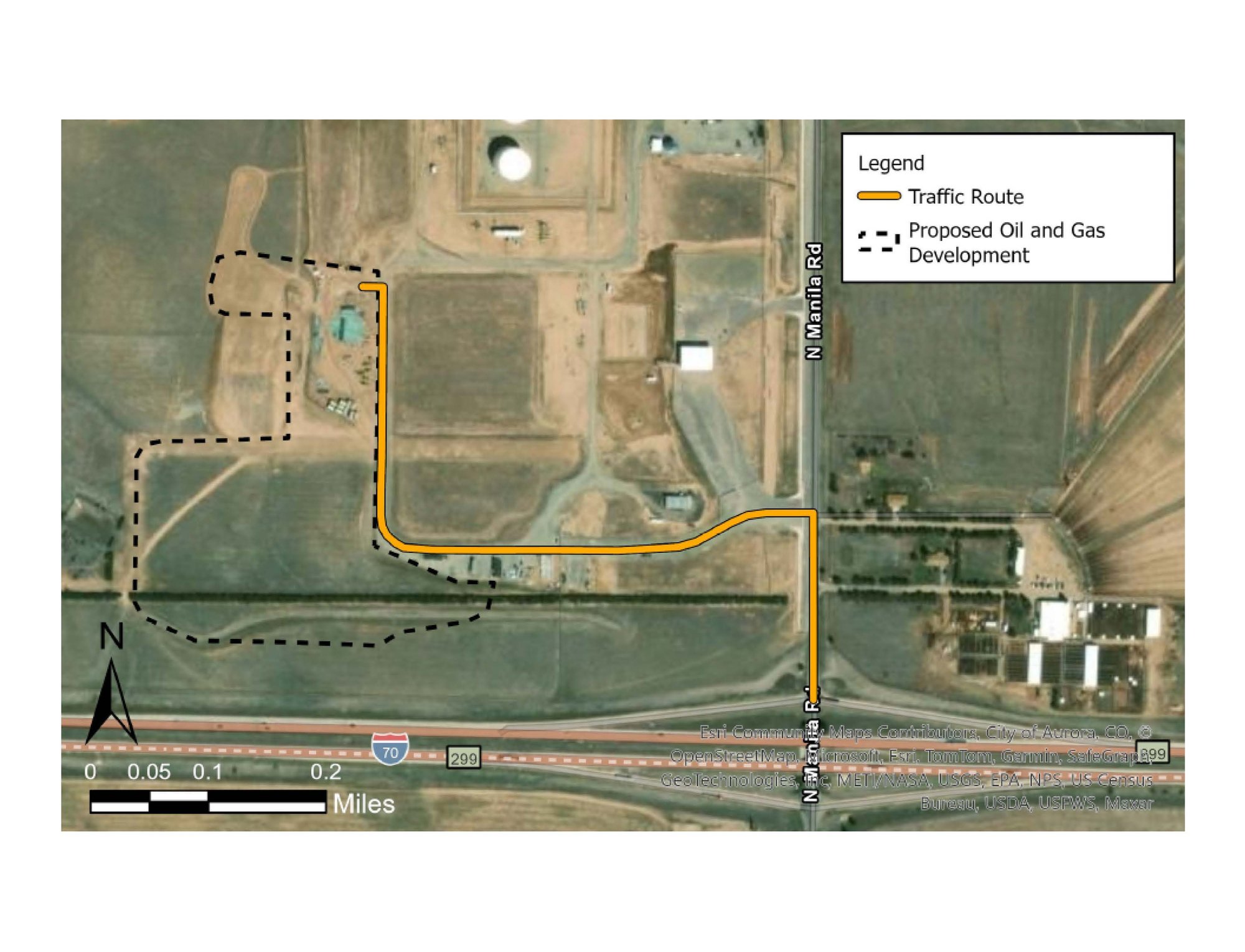

The Bennett D Pad is located in near the intersection of Manilla Road and Interstate 70 in Adams County, and is collocated with existing infrastructure. The proposed pad will occupy approximately 23 acres during pre-production (drilling and completions), scaling down to approximately seven and a half acres during production. The plan proposes five drilling spacing units and will include up to 26 new horizontal wells.

Haul Route

Proposed Haul Route Directions

SM Energy developed the proposed haul route to minimize the traffic in the area for our pre-production operations (construction, drilling, and completions). The proposed haul route utilizes less than a quarter mile of Adams County Road before accessing Interstate 70. No traffic will be directed north on Manilla Road.

Entering the Well Pad:

- Take Exit 299 off of I-70

- Proceed north on Manilla Road for approximately one tenth of a mile

- Turn left on the existing access road to the location

Exiting the Well Pad:

- Turn right to proceed south on Manilla Road

- Travel approximately one tenth of a mile

- Enter east or west bound on I-70

The yellow line on the map indicates this haul route.

Estimated Development Plan Timeline

Average Daily Truck Trips: 24

Average Daily Employee Trips: 10

Duration [Days]: 60

Operating Hours: Daylight Hours

Average Daily Truck Trips: 24

Average Daily Employee Trips: 36

Duration [Days]: 175

Operating Hours: 24 hrs/day

Average Daily Truck Trips: 90

Average Daily Employee Trips: 66

Duration [Days]: 308

Operating Hours: 24 hrs/day

Average Daily Truck Trips: 9

Average Daily Employee Trips: 10

Duration [Days]: 60

Operating Hours: Daylight Hours

Average Daily Truck Trips: 5

Average Daily Employee Trips: 2

Duration [Years]: 30

Operating Hours: Daylight Hours

Air Quality – Air Monitoring

Smart Engineering to Lessen Our Impact

- Electric drilling: We’ll use electric-powered rigs instead of diesel ones to reduce emissions.

- Cleaner, best-in-class engines: During completions, we'll use the cleanest available engines, tier IV, similar to the newest, most efficient truck engines.

- “Oil Tankless Design”: Instead of having traditional tanks for oil, this pad will use pressurized vessels for gas and oil before routing it though pipeline, significantly reducing truck traffic.

- Using electricity: We're always looking for ways to switch from gas or diesel power to cleaner electricity wherever it makes sense. The facility on the pad will run on electricity for the life of the pad.

Checking for Leaks and Keeping the Air Clean

- Regular checks by sight, smell, and sound: During all phases of our work, our teams regularly walk around and carefully look, smell, and listen for any signs of leaks from equipment that holds oil, gas, or chemicals.

- High-tech leak detection with special cameras: We have a strong program to find and fix leaks quickly. We use special cameras that can "see" gas leaks that we can’t. We start using these cameras during drilling and continue checking for leaks throughout the entire life of the site.

- Government approval for air monitoring: Our plan for monitoring air quality must be reviewed and approved by Adams County and Colorado's main health and environmental agency, the Colorado Department of Public Health and Environment. This ensures our methods meet strict state and local standards for keeping the air clean.

Ground Water Protection

- Lining the Ground during drilling and construction: We put down a heavy-duty plastic sheet (a polyethylene liner, like a thick tarp) on the ground. This stops any spills from potentially soaking into the soil or reaching nearby water.

- Building a safety barrier around equipment: A containment system is built around separation equipment and tanks to ensure if a leak occurs, there will be no impact to the environment.

- Having a spill prevention plan: We create a detailed plan specifically for each site that explains exactly how we'll prevent spills and what we'll do in the unlikely event one happens.

- Thirty-two-foot sound walls will be constructed around the majority of the well pad area.

- Continuous sound monitoring terminals will be placed strategically between the pad and residential building units.

- A "quiet completions fleet" will be used for hydraulic fracturing (completions) operations.

- Permanent production facility will be powered by grid power.

- Lighting will be angled downward to limit the halo effect off location & placed at reasonable heights to limit spillage off location.

- Thirty-two-foot sound walls also minimize lighting impacts to surrounding receptors.

- No lighting will be present on the permanent production facility.

Sealed Fluid Management:

- We use a "closed-loop" system, meaning all drilling fluids are contained and recycled, eliminating open pits that can emit odors.

Odor-Conscious Materials:

- We specifically choose Group III drilling fluids, known for their very low odor profile. We also remove drilling waste daily.

Modern Facility Design

- Our production facilities will be powered by clean, reliable grid electricity, avoiding odors associated with generators.

- We will utilize instrument air for pneumatic controls and a pressurized maintenance vessel for maintenance operations, which eliminates gas that would normally be vented to the atmosphere during these operations.

- The entire location will be designed without oil storage tanks, further reducing potential odor sources.

Public Filings

- Form 2A: (Location Assessment, Exhibits and Plans): https://ecmc.state.co.us/weblink/DownloadDocumentPDF.aspx?DocumentId=7264682

- Form 2B: https://ecmc.state.co.us/weblink/DownloadDocumentPDF.aspx?DocumentId=7264439

- Form 2C: https://ecmc.state.co.us/weblink/DownloadDocumentPDF.aspx?DocumentId=7136407

Permitting Timeframe

- ECMC approved Oil and Gas Development Plan (OGDP) on October 1, 2025.

- Adams County approved the Oil and Gas Facility (OGF) on October 28, 2025.